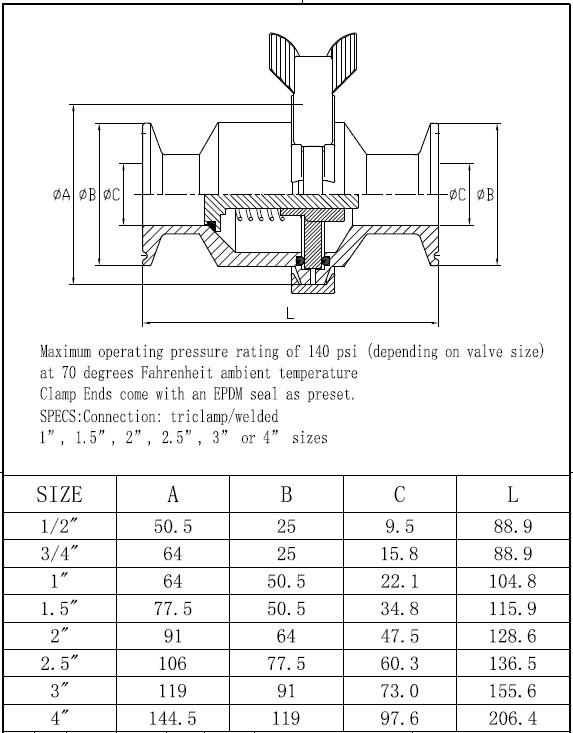

AV-3C Sanitary Check Valve with Tri-clamp Ends

Specification:

Sizes are available from 1/2″ to 4″ (1/2″, 3/4″, 1”, 1 1/2″, 2″, 2 1/2″, 3″, 4″)

DN15 to DN100 (DN15, DN20, DN25, DN40, DN50, DN65, DN80, DN100)

Valve body can be AISI 304 or AISI 316L.

Valve seat: EPDM, VMQ (silicone), Viton (FPM) for choose from, all complying with FDA 21CFR177.2600.

End connection can be butt-welded, sanitary clamp, threaded or others upon request.

Max. working pressure: 145psi (10bar)

Opening pressure: 4.5psi/0.3 bar (DN25/1″), 3 psi/0.2 bar (DN32/0.75″ to DN40/1.5″), 1.5 psi/0.1 bar (DN50/2″ to DN100/4″)

Working temperature range: 14 ~ 248°F (-10 ~ 120°C) with EPDM seat.

Surface treatment: Ra 32μin (0.8μm) as default, others available upon request.

Sanitary Check Valve Application

Sanitary check valve, also known as “non-return valve”, is designed for use in process piping installations to prevent reverse flow. AV-3C series is a spring check valve with tri-clamp ends.

Sanitary Check Valve Specification

Sizes are available from 1/2″ to 4″ (1/2″, 3/4″, 1”, 1 1/2″, 2″, 2 1/2″, 3″, 4″)

DN15 to DN100 (DN15, DN20, DN25, DN40, DN50, DN65, DN80, DN100)

Valve body can be AISI 304 or AISI 316L.

Valve seat: EPDM, VMQ (silicone), Viton (FPM) for choose from, all complying with FDA 21CFR177.2600.

End connection can be butt-welded, sanitary clamp, threaded or others upon request.

Max. working pressure: 145psi (10bar)

Opening pressure: 4.5psi/0.3 bar (DN25/1″), 3 psi/0.2 bar (DN32/0.75″ to DN40/1.5″), 1.5 psi/0.1 bar (DN50/2″ to DN100/4″)

Working temperature range: 14 ~ 248°F (-10 ~ 120°C) with EPDM seat.

Surface treatment: Ra 32μin (0.8μm) as default, others available upon request.

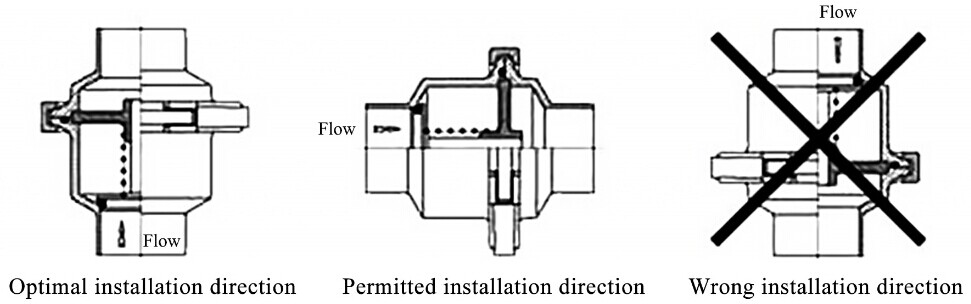

Sanitary Check Valve Working Principle

A check valve opens when the pressure below the valve plug exceeds the pressure above the valve plug and the spring force. The valve closes when pressure equalization has been achieved. The below picture shows the right installation:

|

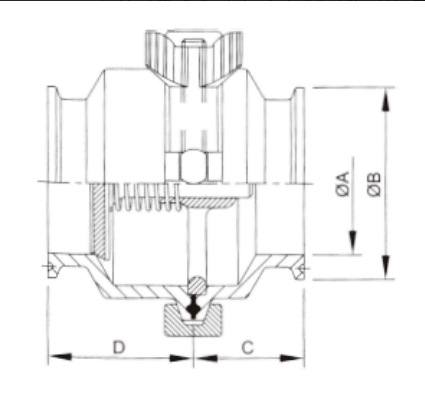

SIZE | A | B | C | D |

| 1/2″ | 9.5 | 25.2 | 28.5 | 39.5 | |

| 3/4″ | 15.8 | 25.2 | 28.5 | 39.5 | |

| 1″ | 22.1 | 50.5 | 34 | 48 | |

| 1.5″ | 34.8 | 50.5 | 36 | 48 | |

| 2″ | 47.5 | 64 | 36 | 48 | |

| 2.5″ | 60.2 | 77.5 | 36 | 48 | |

| 3″ | 72.9 | 91 | 36 | 48 | |

| 4″ | 97.6 | 119 | 47 | 54 |

| Technical Parameters | |||

| Steel material | Product wetted steel parts | AISI 304 or 316L

(1.4306 / 1.4404) |

Provided with material inspection report |

| Other steel parts | AISI 304 | ||

| Seal material | Standard | EPDM | All seal materials comply with FDA 21CFR117.2600 |

| Options | VMQ (Silicone) or Viton (FPM) | ||

| Pressure | Working pressure | ≤145psi (10bar) | |

| Opening pressure: | 4.5psi/0.3 bar (DN25/1″), 3 psi/0.2 bar (DN32/0.75″ to DN40/1.5″), 1.5 psi/0.1 bar (DN50/2″ to DN100/4″) | ||

| Temperature | Working temperature | 14 ~ 248°F (-10 ~ 120°C) with EPDM seat. | |

| Surface treatment | Inside surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) | |

| Outside surface treatment | Ra 32 ~ 64µin (0.8 ~ 1.6µm) | ||

| Connection | End connections can be butt-welded, sanitary clamp, threaded or others upon request. | ||

/wp-content/uploads/2016/01/AV-3-Sanitary-Check-Valves.pdf |