Category: Sanitary Valve Applications

Which Industries Need Pressure Relief Valves?

What is the Purpose of Pressure Relief Valves? A pressure relief valve is a crucial safety device in pressurized systems. Its core function is to provide automatic overpressure protection. When system pressure exceeds the preset safety limit due to process fluctuations, equipment failure, or abnormal conditions, the pressure relief valve opens automatically. Releasing a certain […]

Read moreTitanium vs. Stainless Steel Sanitary Ball Valves

Choosing the right materials is a critical decision, since it directly impacts the quality of sanitary ball valves. Titanium and Stainless Steel stand out because of their superior performance. While both are excellent, they serve different purposes. Understanding their unique properties will guide you to the correct choice. Stainless Steel Sanitary Ball Valves Stainless steel […]

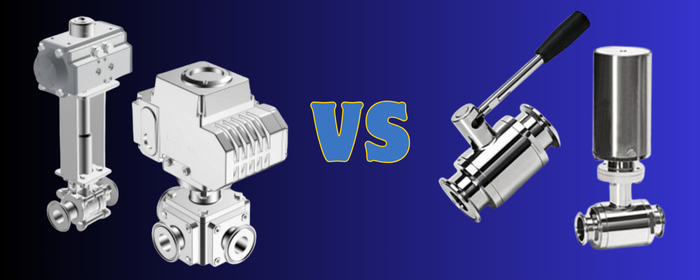

Read moreGlobe Valves vs. Ball Valves

Globe valves excel in precise flow control & throttling, while ball valves are ideal for quick on/off service with minimal pressure drop. Differences between Globe Valves and Ball Valves 1. Different Working Principles A Globe Valve has an internal disc that moves up and down, acting like a plug, and a seat. By rotating the handwheel, the […]

Read moreGate Valve vs. Globe Valve vs. Check Valve – Principles, Applications, and Differences

Gate valves, globe valves, and check valves are three of the most fundamental and common types of valves. While their external appearances can sometimes be similar, their internal structures, working principles, and core missions are distinctly different. What is a Gate Valve? A gate valve is intended for the ON/OFF operation of fluid flow, involving […]

Read moreWhich Sanitary Valves Need to Be Installed on a CIP Cleaning Solution Storage Tank?

Sanitary CIP cleaning systems are important in food and pharmaceutical manufacturing. The cleaning solution tank is at the center of the system. The tank valves play a key role in determining how efficient the cleaning process is and how secure the system is. Choosing and installing suitable valves avoids contamination and buildup. It further improves […]

Read moreWhat are the Requirements for Bio-Pharmaceutical Sanitary Valves?

Aseptic fluid control systems in the biopharmaceutical industry depend significantly on valves. Efficiency, quality, and production safety all depend directly on their reliability and performance. Sanitary biopharmaceutical use valves are specifically designed for this particular industry’s unique requirements. They must meet several requirements in materials and design the guarantee drug safety. 4 Core Requirements for […]

Read moreSanitary Valves in Our Daily Life

How Are Valves Used in Everyday Life? Everyone has heard the word “valve” before. And almost everyone is familiar with using common valves. We all use valves in our daily lives, from our kitchen to other areas like the garden or bathroom. Sanitary valves refer to a type of valve used in places with high […]

Read moreWhat Kinds of Valves are Used in Different Industries?

Urban Gas Urban gas accounts for 22 percent of the total natural gas market, with many types and large volumes of valves. Ball valves, plug valves, pressure relief valves, and relief valves are often required. Urban heat supply A large number of metal-sealing butterfly valves, horizontal balancing valves, and directly buried ball valves are needed […]

Read moreSanitary Security And Inspections For Food Industry

Consumers should never lose awareness of the sanitary threats brought by convenience foods and drinks. Some convenience stores may be carried and sold food improperly prepared or even expired, which will probably bring the consumers serious physical upset and disorder. There are definite and specific sanitary standards for every step during food and beverage preparation. […]

Read moreSanitary Diaphragm Valves for Medicine

What is a sanitary diaphragm valve? A sanitary diaphragm valve is considered a highly hygienic valve due to its mode of operation. This technique is called “input from above.” The upper inlet facilitates the welding and extraction of the clamps during the maintenance of the valve. Sanitary diaphragm valves in the pharmaceutical industry Sanitary diaphragm valves […]

Read more