Why do We Choose Stainless Steel in Sanitary Process Systems?

What is it that makes stainless steel “stainless” and why is stainless steel the material of choice for clean process segments? This post will concentrate on those inquiries and give knowledge into a term that is regularly misrepresented.

What is the advantage of stainless steel valves?

Because valves are meant to open and close, corrosion can cause big issues. If there is too much corrosion, this may cause a Ball Valve to break or become unable to move. Stainless Steel Ball Valves will hold up much better to harsher water types. This will ensure a longer-lasting valve.

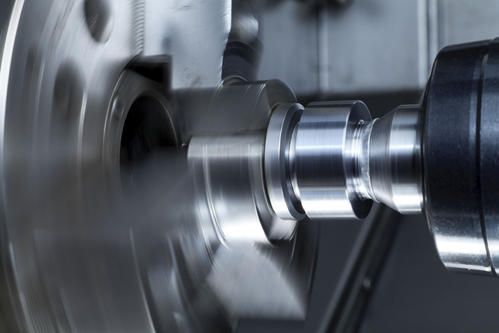

Why are valves made of stainless steel?

Why stainless steel? Stainless steel is steel and so it is typically very strong. This gives it great pressure and temperature resistance. This plus their toughness and strength make stainless steel a useful material option for compact miniature flow control valves.