Sanitary Valves: Need for Hygienic Applications

Sanitary valves refer to devices that are used in applications where more importance is given to cleanliness and sterility. These valves can be classified into different categories depending upon the type of valve, the material used to manufacture them, and actuation type. Classification according to actuation is possible because some of the valves are manual while others may include electric or pneumatic type.

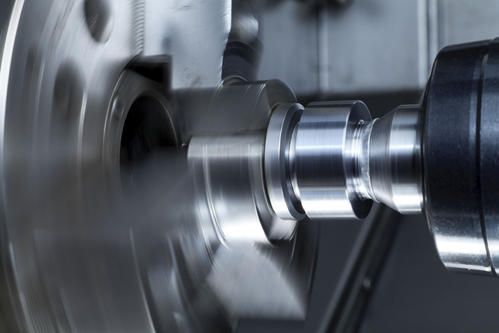

Categorization is also possible on the basis of the material used to construct the sanitary valve. The material used for the purpose may be steel, bronze, cast iron, forged steel, brass, or stainless steel. Another way of classification depends upon the type of valve. Gate valve, ball valve, butterfly valve, swing check valve, air relief valve, and globe valves are some of the examples of this kind of classification. Thus, there are a variety of sanitary valves available for us to choose from based on our different kinds of needs.

It is essential to have a little information about all these varieties to get a thorough understanding of sanitary valves used in various applications. Let us begin with swing check valves. If you wish that the water should not backflow into the pond from the filter then you have no other option but to use a swing check valve. Moreover, if you want to keep the pump primed, then also you have to use this valve. Although, these valves are not frequently used as compared to other types of valves yet you can get different sizes of check valves from the market.

Gate valves, as the name itself, suggests acting like a gate. These are suitable for applications that demand a minimum flow of water. The part that either lets the water flow or stops is called sluice. That is why these valves are also called sluice valves. The flagged ends of valves are designed completely in accordance with the flange dimensional standards of the industry.

When we talk about globe valve, the name itself again is sufficient to say a lot about its structure. Old models were completely spherical in shape but the shape of newer ones is not fully spherical. When the application in question requires more precision regarding control of flow then the globe valve is an ideal choice. Fine-tuning of flow control is possible with the help of a plug or disk either completely or partially fitted into a plate with a hole.

Although you can get a custom-designed globe valve to meet your specific requirements yet three main designs are more popular. When the outlet is at right angles to the inlet then it is called angle type valve. The working of Y design depends on linear action between port and axis. Multi-piece design is made by bolting all valves together.

Butterfly valves are made of a circular plate and a rod that goes through its diameter. The name butterfly valve is given because of its outer shape. By rotating it from 0 to 90 degrees, you can precisely control the flow of liquid or stop it completely. You may choose a very suitable type of sanitary valve, judging from the usages and the pressures applied.