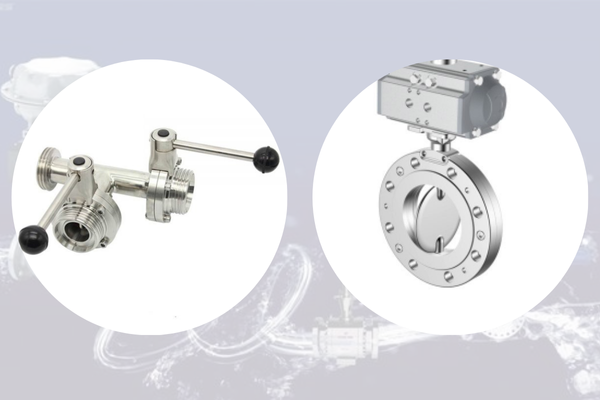

What’s the Difference between Pneumatic Butterfly Valves and Regular Ones?

The most basic difference is in the way they are driven. It’s the difference between a manual transmission car and an automatic. Both are made to drive, but the means through which you drive them can be quite different.

By the phrase “regular butterfly valve,” we’re typically talking about manual butterfly valves. These are completely reliant on manual labor to operate. You will have a hand lever or a wheel. Someone has to be around in order to turn it by hand to open or close the valve. They’re cost-effective, reliable, and perfect for easy shut-off applications where you don’t need to use them very often, like maintenance

Conversely, a pneumatic butterfly valve is like having a manual valve and giving it muscles—a pneumatic actuator, that is. Instead of using human effort, it is powered by compressed air. When the control room sends an electric signal, a solenoid valve governs compressed air into the actuator, which rapidly rotates the valve disc.

This change in the mode of powering the valve has some real benefits:

- Automation and remote control: A big one. Pneumatic valves can simply be added to PLC or DCS systems. So you operate them remotely—automate processes en masse. Click a mouse in the control room to operate hundreds of valves plant-wide.

- Speed and efficiency: Since frequent switching or quick shut-off is needed, pneumatics are much faster than manual action. They can be opened or closed within seconds. This increases efficiency and renders operations safe.

- Greater power: In large pipes or high-pressure situations, it may be hard—or impossible—for a person to operate a manual valve. Pneumatic actuators deliver firm, consistent torque and endure brutal conditions without difficulty.

- Safety and flexibility: Pneumatic valves can be installed in hard-to-reach areas, too hot to touch, or where there are hazardous substances. That makes them a good choice for tough environments.

True, pneumatic valves do need extra equipment—such as an air compressor for energy and wiring for control signals. That’s more expensive upfront than manual valves.

So how do you choose? It’s relatively easy. If you just need a simple valve that will only be used occasionally, a manual valve is convenient and cheap. But if your use involves automation, remote control, high usage, or safety interlocking, then a pneumatic valve is the way to go. The benefits of increased efficiency and safety are definitely worth the expenditure.

We don’t just provide superior manual and pneumatic butterfly valves at Adamant Valves—we also help you choose the right solution based on your automation and process needs. We are even able to provide the matched pneumatic actuators and accessories. Our technical engineers are always ready to consult you.