Where Should a Check Valve Be Installed?

How is the installation location of a check valve determined? What is the difference between installing a check valve before the pump versus after the pump? Where is pre-pump installation suitable? Check valves are often used with other valves. So, where should the check valve be installed when used in combination with other valves? Let’s explore these questions below.

The Function of a Check Valve

A check valve, also known as a non-return valve, is an automatic valve. It relies on the pressure of the flowing medium in the pipeline to open and close the disc. The disc closes when the medium stops flowing. It effectively prevents the backflow of the medium in the pipeline. This plays a significant role in ensuring pipeline safety.

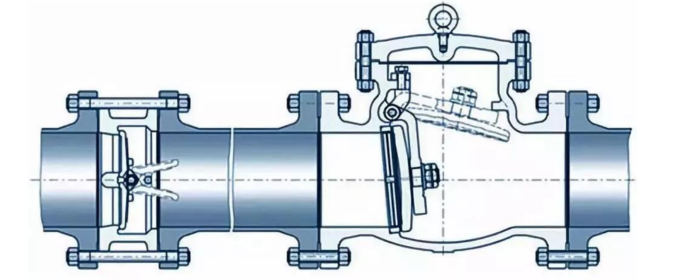

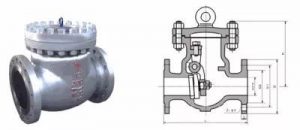

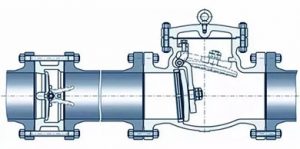

Check valves can be classified by structure into three main types: lift check valves, swing check valves, and butterfly-type check valves.

Lift check valves can be vertical or straight-through. Swing check valves are divided into single-disc, double-disc, and multi-disc types. Butterfly-type check valves include double-disc and single-disc designs.

These types can have four connection methods: threaded, flanged, welded, or wafer-type.

Before or After the Water Pump?

The purpose of installing a check valve is to ensure the correct flow direction within the pump system and guarantee the pump’s normal operation. So, should it be installed before or after the pump? There are two primary scenarios:

One method is installation at the end of the vertical suction pipe before the pump. This is often called a foot valve. The goal is to avoid having to prime the pump each time it starts. If the pump and the suction pipe are empty, the pump will just spin without moving water. The pump must be full of water to work. This installation is used when the pump is located above the liquid level, also known as a suction lift application.

The other method is installation after the pump. This approach is used when the liquid level is above the pump. It makes it convenient to start and stop the pump without closing the outlet valve. It prevents backflow, especially in common header pump systems.

Before or After the Outlet Shut-off Valve?

The check valve must be installed before (upstream of) the outlet control valve. This allows for maintenance of the check valve. A typical pump discharge line has the following order: first a flexible connector (for vibration), then the check valve, and after that the isolation valve (such as a butterfly valve, gate valve, or globe valve).

- Installing Check Valve First, Then Gate/Butterfly Valve

- Advantage: Protects the check valve. In parallel pump systems, if one pump is off and its outlet valve is closed, the shock from starting another pump is absorbed by the gate/butterfly valve. If the check valve fails, the inlet and outlet valves can be closed to isolate it for repair.

- Disadvantage: Who protects the gate/butterfly valve? There have been instances where the disc of a butterfly valve was shattered by water hammer.

- Installing Gate/Butterfly Valve First, Then Check Valve

- Advantage: Protects the gate/butterfly valve. The shock force is borne by the check valve.

- Disadvantage: Who protects the check valve? Check valves open and close based on pressure differentials. Unstable flow conditions can cause the valve to cycle rapidly, reducing its lifespan. Furthermore, if the check valve fails, repairing it—especially in a common header system—requires a full system shutdown.

In general, because check valves operate frequently, their internal parts and seals are prone to wear. To facilitate repair and avoid a single check valve failure shutting down the entire system, the check valve is typically installed before the outlet gate or butterfly valve.