Detailed Explanation of Control Valve Cv Value: Definition, Measurement and Sizing Guide

The performance of the control valves directly influences the general operational efficiency and stability in fluid control systems. Among key parameters, the Cv value acts as a critical metric to evaluate flow capacity, hence playing a very vital role in valve selection and system design.

What is the Cv Value?

Cv, or Flow Coefficient, is a quantitative measure of the flow capacity of a valve under specific test conditions. It is defined as: the volume of water in U.S. gallons per minute that will pass through a fully open valve at a pressure drop of 1 pound per square inch (approximately 7 kPa), with the water temperature at 60°F (15.6°C).

Quite simply, the Cv value represents the level of resistance a valve imposes on fluid flow:

- A high Cv value → Less the pressure loss for fluid passing through a valve → Higher the flow capacity of that valve.

- A lower Cv value → Higher pressure loss, during fluid passage through the valve → Reduced flow capacity of the valve.

How to Measure the Cv Value?

The Cv value of the valve is not a theoretical calculation but must be determined through actual testing and calculation. The standard measurement method will be as follows:

- Test Conditions:

Valve Condition: Fully opened.

Test Medium: Water (Temperature at 15.6°C)

Pressure Drop Setting: The pressure drop should be kept constant at 1 psi, which is roughly equivalent to 7 kPa.

Measurement Parameter: The flow rate through the valve per unit time.

- Calculation Formula:

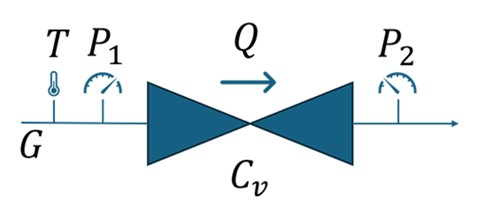

According to the test data, there is the possibility of determining the Cv value by the basic formula of flow:

Cv = Q × √(G/ΔP)

- Q: Flow rate [U.S. gallons per minute, GPM]

- G = Specific gravity of the fluid = 1.0 for water

- ΔP: Pressure drop across the valve (psi)

It is necessary to include the factors such as viscosity correction and gas compressibility correction in proper calculation under different media and conditions.

How to Determine Valve Size Using the Cv Value?

Adequately choosing the valve size is essential for maintaining a properly running system. Here is a three-step method for sizing valves using the Cv value :

Step 1: Determine the Cv Value Required

Calculate the value of Cv needed at operating conditions from the system:

Determine Process Parameters:

- Maximum, normal, and minimum flow rates.

- The pressure of the inlet and the outlet of the valve is

- The properties of the medium – density, viscosity, temperature and phase.

Choose formula for calculation:

- For liquids: Consider flashing, cavitation, etc.

- For gases/steams: Take into consideration compressibility, critical pressure drop ratio.

Use Computation Tools:

It is highly recommended to apply professional Cv value calculators-as our online tool-calculate the answer automatically using several correction factors that might influence the calculation.

Step 2: Correct Valve Sizing

Compare to Rated Cv Value:

Consult the valve manufacturer’s Cv value table.

Select a valve whose rated Cv value is equal to or somewhat greater than the calculated required Cv value.

It is normally advisable to operate the valve within 70-90% of its rated Cv value in order not to work at very low openings.

Consider Other Factors:

Types of valves, like ball valves, butterfly valves, globe valves, etc.

Material compatibility of the bearing with the process fluid, including corrosiveness of the medium, temperature, and pressure ratings.

Compatibility with the actuator.

Installation Space Limitations.

Step 3: Verification and Adjustment

- Verification of system simulation: Use professional software for the stimulation of real performance of the valve in the system.

- Safety Margin: Check the suitability of the valve under extreme operating conditions.

- Change Where Necessary: In the case of large deviations between the results of calculations and expectations, reevaluation of parameters or choice of another valve size may be required.

Engineering Application Warning: The Consequences of Improper Selection of the Cv Value

For practical engineering, wrong Cv value selection may cause serious consequences. For example, in the building water supply system:

If the Cv value is too small for a given control valve, then that valve becomes a “bottleneck” for that system, with the following consequences:

- Frequent starts/stops of the pumps, or steady operation under high load.

- This has caused a huge rise in energy loss.

- Severe pressure fluctuations in pipelines leading to loosening and leakage at connections.

- Premature damage of the pump because of chronic overload.

If the value of Cv is too large, the following problems may occur:

- Poorer accuracy of control – often operating at low openings.

- Poor control stability.

- Wasted system investment.

Overview

The Cv value of the control valve is an important bridge that connects valve performance and system requirements. Accurately understand the definition of the Cv value; scientifically measure the value of the Cv of the existing valve; accurately calculate the required value according to the actual conditions, and choose the correct size of the valve. If these are done, the engineer can achieve the following:

- Optimize the energy efficiency of systems and reduce operational expenses.

- Provide better accuracy and stability for controls.

- Extend the service life of equipment.

- Reduce the amount of maintenance required and prevent failure.

In this context, modern industrial automation and intelligent control put forward higher requirements for the precise application of the Cv value, not only in the realm of technology but also on a scientific basis that will offer efficient and reliable fluid control systems. It is recommended during system design and modification that engineers fully exploit professional calculation tools and manufacturer data to ensure accuracy and rationality in the application of the Cv value.

Related Articles: