Single Check Valve vs. Double Check Valve

What is a Single Check Valve?

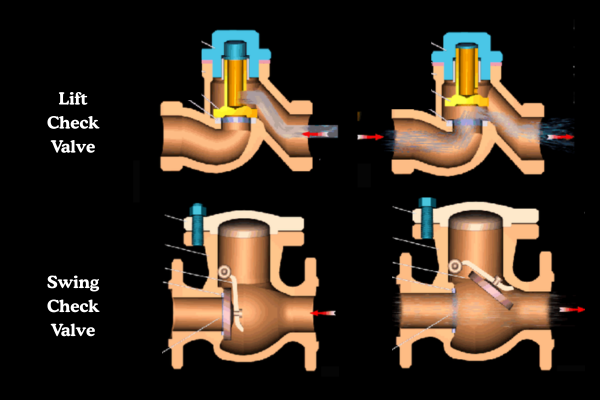

A single check valve, as the name suggests, usually consists of a single flap. The flap is fixed to the valve cover and operates by rotating to open or close the valve. When fluid flows forward, the flap rotates upward to open the valve, allowing fluid to pass through freely. Alternatively, when fluid flows backward, the flap is pushed by the reverse force of the fluid, rotating downward to close the valve and prevent backflow. See Figure 1.

Fig. 1 How a single check valve works

The single check valve has a simple structure and is easy to maintain. It is suitable for low-flow and high-pressure pipeline systems. However, it does not close completely and may leak. In high-flow or large-volume systems, the valve may not close quickly enough, which can reduce the efficiency of the pipeline system. Also, since it has only one flap, if it wears out or gets stuck, the valve loses its ability to prevent backflow.

Therefore, the safer double check valve was developed.

What is a Double Check Valve?

A double check valve has two independent check valves installed in series within one valve body. It also uses rotating flaps to open and close the valve. Its working principle is the same as that of a single check valve. When fluid flows forward, the valves open, allowing fluid to pass through freely. When fluid flows backward, the valves close to prevent backflow. Its advantage is that it closes more completely and provides better leakage prevention. Thus, it is more suitable for high-flow systems than a single check valve. Moreover, in high-flow or large-volume systems, it closes more quickly and does not affect pipeline efficiency.

Since the double check valve has an extra flap, it provides an additional layer of protection. Even if one flap fails, the other is likely to still work properly. However, no valve is perfect. The double check valve has a more complex structure and higher cost. It may also produce some noise and vibration when backflow occurs.

Single or Double?

A check valve is a backflow prevention device used to avoid cross-contamination. When choosing between a single or double check valve, factors such as fluid properties, flow rate, and pressure must be considered. Generally, for low-flow and low-pressure pipeline systems, a single check valve is sufficient. For high-flow and high-pressure systems, a double check valve is more suitable.

In practical applications, especially in water supply systems, you may often hear of a more advanced device: the double check valve with an atmospheric vent. This device adds a discharge valve to the double check valve. When the pressure between the two check valves exceeds the upstream inlet pressure, indicating possible backflow, the discharge valve opens automatically and releases the backflowing water to the outside. This provides a third layer of protection.

Recommended Products

High Performance Swing Check Valve AV-3P Three Piece Check Valve Sanitary Spring Check Valves with Tri-Clamp