Category: Sanitary Pump

Volumetric Sanitary Pump Classification

There are lots of volumetric sanitary pump types available, but which one is right for you? Volumetric sanitary pumps, in which its operating principle is based on hydrostatics, the increase in pressure is made by the thrust of the walls of the chambers that vary their volume. In this type of pump, in each cycle, […]

Read moreBenefits of Applying Sanitary Pumps

What are the applications of sanitary pumps? Sanitary pumps are designed to handle products related to the pharmaceutical, cosmetic, health, dairy and food industries. These industries are generally based on equipment that can be easily and quickly cleaned or sterilized at regular intervals. This ensures that no product contamination occurs. Such products may include liquids […]

Read moreHow to Install Sanitary Pumps?

The following are the factors to consider when installing sanitary pumps: Straight Lengths of tubes It is of great importance to have 4-6 tube diameters of inlet tubing that is straight into the pump when installing a sanitary pump. The continuous length of the inlet enables the flow to be laminar into the pump. Preventing […]

Read moreThe Benefits of Utilizing Sanitary Pumps

Sanitary pumps are designed to handle products related to the pharmaceuticals, cosmetic, healthcare, dairy, and food industries. These industries generally rely on equipment that can be easily and quickly cleaned or sterilized at regular intervals. This ensures that no contamination of products takes place. Such products may include liquids that dry quickly or form films, […]

Read moreHow Sanitary Pumps Work in Beverage Industry

Sanitary pumps are mostly used to convey or pressurize fluids in a system. Using the pumps, you can reduce the pressure or put on or off the flow of the liquids. Due to the function of the pumps, the manufacturer should ensure that they are made with consideration and of the highest standards that rhyme […]

Read moreMaterials Used for Sanitary Pumps

Sanitary pumps have a wide variety of uses in all areas of life. They are designed for basic applications such as applications requiring clean, sterile processing. The most common use of these sanitary pumps has been observed in the field are in the food industries, dairy companies, pharmaceutical processes, the medical sector, and other segments of […]

Read moreCompetitive Edge of New Sanitary Pump Designs

Economic pressures are forcing pharmaceutical manufacturers to look for ways to become more competitive. Many companies realize that they need to reduce their operating costs while maintaining or improving the quality of products. Recognizing the needs of their customers, many OEM manufacturing engineers write specifications to ensure that the latest innovations will reduce energy consumption, […]

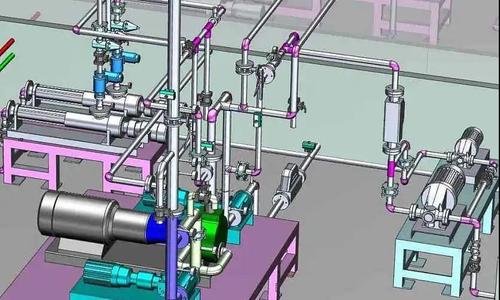

Read moreOverview of the Sanitary Pump

Food processing is mainly divided into three major processes, namely incoming material, semi-finished product processing, and finished product, in which each part is more or less involved in the sanitary pump. For example, chocolate processing needs pumps capable of conveying high viscosity media, wastewater treatment needs pumps that are resistant to abrasion and corrosion, and […]

Read morePacking Failures and Troubleshooting for Sanitary Pumps

Why Packing Fail Generally, the packing of a sanitary pump fails for two reasons: normal deterioration and improper usage (usually considered as premature failure). Normal Deterioration Packing is designed to wear and tear due to pressure and lubricant consumption. With normal usage, a portion of lubricant in the packing material would lose. This is normal […]

Read moreWhat are Sanitary Pumps?

What is a Sanitary Pump? Sanitary pumps are specialized equipment used to pump hygienic liquids and slurries through industrial processing pipeline systems. A sanitary pump is a critical agent in the transportation of products meant for human consumption or contact, such as pharmaceuticals, dairy products, beverages, food, cosmetics, food additives, fine chemicals, and so on. […]

Read more