What Are the Types of Sanitary Butterfly Valves?

Sanitary butterfly valves are widely used in industries such as food, beverage, pharmaceuticals, and bioengineering. Their core design principles focus on being dead-leg free, easy to clean, sterilizable, and corrosion-resistant.

What Does “Sanitary Grade” Mean? More Than Just Clean

Unlike common water taps or industrial valves, “sanitary grade” represents a set of extremely stringent design requirements.

Its core principles are: dead-leg free, easy to clean, corrosion-resistant, and sterilizable.

- Dead-leg Free: This means there must be no gaps, grooves, or edges between the valve’s inner wall and moving parts where microorganisms or product residue could hide and proliferate.

- Easy to Clean: Production lines require thorough “Cleaning-in-Place (CIP)” after each batch. This involves cleaning without disassembling equipment, using high-temperature cleaning agents and water directly. The valve design must ensure cleaning fluids can flow unimpeded through every corner.

- Sterilizable: In pharmaceuticals and bioengineering, “Sterilization-in-Place (SIP)” is also necessary, often using pure steam at temperatures of 121°C or even higher. The valve must withstand this high-temperature, high-pressure challenge to ensure a sterile state.

These specific requirements shape the unique form and function of sanitary butterfly valves.

So, what types of sanitary butterfly valves are available?

Connection Types for Sanitary Butterfly Valves

How the valve connects to the pipeline determines the system’s sealing integrity and ease of disassembly. The main types in the market are:

- Clamp Type (Tri-Clamp):

This is the most common type. It uses a standard three-piece stainless steel clamp and a food-grade elastomer gasket, functioning like a powerful hand that tightly clamps the valve body and pipeline together. Installation or removal is quick, achieved by simply turning a few screws, facilitating routine deep cleaning and equipment maintenance. It’s like giving the pipeline system “Lego” interfaces – flexible and efficient.

- Welded Type:

For permanent pipelines requiring absolute zero dead legs, welding is the best option. The valve ends are fused completely with the pipeline via precise automatic orbital welding, creating a smooth, mirror-like continuous internal surface. This method leaves no gaps and offers very high strength, but the trade-off is that it’s nearly impossible to disassemble once welded. It’s commonly used in critical systems within the pharmaceutical industry, such as purified water and Water for Injection (WFI) lines.

- Threaded and Flanged Types:

Threaded connections are tightened via screw threads and are suitable for spaces with limited access. Flanged connections, on the other hand, are like stamping an official seal on each interface end and then bolting them tightly together. They are robust and are often used for larger diameter or higher-pressure pipelines, such as inlet/outlet lines for large fermentation tanks.

Read more: What are the End Connection Types for Valves?

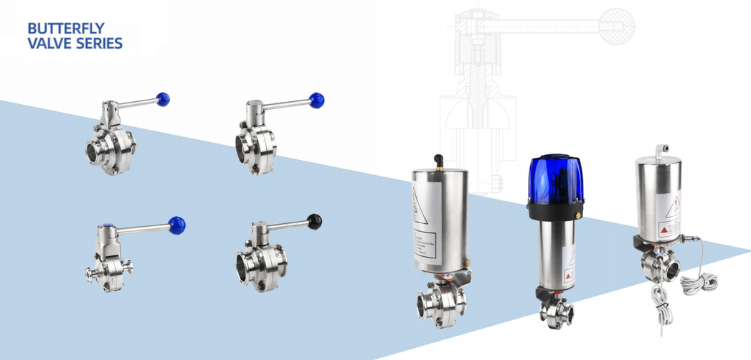

Actuation Methods for Sanitary Butterfly Valves

How do we control the opening and closing of the valve? This depends on their actuation method.

- Manual Actuation:

The most common manual method involves an operator directly moving a lever handle, which often includes a position indicator for rough flow control. When finer flow adjustment is needed, a handwheel is used, allowing precise control of the disc’s opening angle through rotation.

- Pneumatic Actuation:

In modern automated production lines, manual operation is often too slow. Pneumatic butterfly valves address this. Connected to a compressed air supply, they can open or close in less than a second upon receiving an electrical signal. They integrate easily into central control systems, enabling remote control and full automation. Among these, single-acting pneumatic actuators have a built-in safety feature: if air pressure is suddenly lost, a spring automatically returns the valve to a safe position (fully open or fully closed), making them intelligent and reliable.

- Electric Actuation:

If more precise control over the opening degree and complex programmed commands are required, electric butterfly valves are the ideal choice. They contain a miniature electric motor that operates smoothly upon receiving a control signal, making them particularly suitable for process steps requiring fine flow regulation.

AV-1-S0415 Electric Regulating Butterfly Valve

Sealing Options for Sanitary Butterfly Valves

The seal between the valve disc and the body comes into direct contact with the fluid and determines the valve’s chemical resistance and lifespan. Common seal material options include:

- EPDM (Ethylene Propylene Diene Monomer): This is the primary choice for the food and beverage industry. It excels in resisting high-temperature steam (CIP/SIP) and offers good resistance to weak acids, weak alkalis, and cleaning agents.

- FKM (Fluorocarbon Rubber): This material offers excellent chemical resistance. When dealing with oils, organic solvents, and strong acids, its performance far exceeds that of EPDM. It’s often used in pipelines carrying oily products or chemical raw materials.

- Silicone & PTFE: Silicone is highly non-toxic and odorless, often found in high-end pharmaceuticals. PTFE (Teflon) is resistant to almost all chemicals but has slightly less elasticity.

To meet the highest safety standards, double-seal (double-offset) valves are available. These feature two independent seals on either side of the disc, creating an isolated cavity between them. This cavity can be used to introduce a test medium to monitor seal integrity or to inject steam (for SIP), ensuring complete isolation between the media on either side of the valve, providing a fail-safe mechanism.