How A Sanitary Diaphragm Valve Work

Sanitary diaphragm valves are a virtual necessity in the manufacturing processes of the food, beverage, pharmaceutical, and cosmetics industries.

What is a Sanitary Diaphragm Valve?

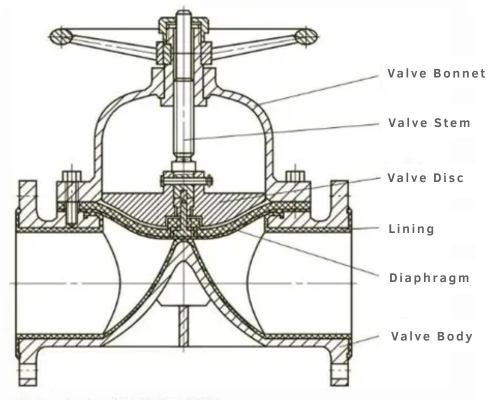

A diaphragm valve is a special type of shut-off valve designed for the highest sanitary standards. Its opening and closing part is a diaphragm made of soft material. It is the diaphragm that separates the valve body cavity from the bonnet cavity. See Figure 1.

Fig 1. Sanitary Diaphragm Valve Structure

The diaphragm valve has three main parts: the valve body, the diaphragm, and the bonnet assembly. ensuring that components above the diaphragm (such as the stem and disc) do not come into contact with the medium. This also prevents the medium from leaking out. Therefore, the valve needs no packing seal structure.

The diaphragm valve uses a corrosion-resistant lined body and a corrosion-resistant diaphragm instead of a traditional plug assembly. The valve body is made of materials like cast iron, cast steel, or stainless steel and lined with various corrosion-resistant or wear-resistant materials. The diaphragm is made of rubber or PTFE, which offers strong corrosion resistance. This design makes the valve suitable for controlling highly corrosive media, including strong acids and alkalis.

What is the Working Principle of a Sanitary Diaphragm Valve?

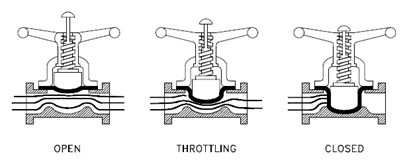

The core of the diaphragm valve’s function lies in the movement of the diaphragm. Pressure is generally applied downwards by rotating a handwheel or via a pneumatic/electric actuator, causing the stem to drive the diaphragm’s movement.

Closed Position:

When the stem presses the diaphragm downwards, the flexible diaphragm deforms and tightly seals against the valve body seat, acting like a reliable plug. This completely blocks the fluid path, achieving a leak-tight seal.

Open Position:

When the stem is raised, the diaphragm fully seats in the bonnet chamber due to its own resiliency, allowing an unobstructed flow path for the fluid. This provides smooth fluid passage with reduced pressure drop and facilitates efficient system cleaning.

Throttling Position:

When the stem is in the middle position, the diaphragm is partially deformed and creates a narrowed restriction along the flow path. When fluid moves in this narrow area, its flow becomes narrowed, enabling rough flow control. However, this position accelerates diaphragm wear and is not the valve’s primary design intention; therefore, its use for throttling is not recommended.

Fig 2. Working Principle of the Diaphragm Valve

What are the Advantages of a Sanitary Diaphragm Valve?

Due to their unique material and structural composition, diaphragm valves offer a series of irreplaceable advantages:

- Low Fluid Resistance: The simple structure of the diaphragm valve results in low fluid resistance and a greater flow capacity compared to other valves of the same specification.

- Leak-tight: The diaphragm isolates the medium from the upper stem chamber, eliminating external leakage without the need for packing.

- Corrosion Resistance: Suitable for corrosive media. The valve body, made of cast iron, cast steel, or cast stainless steel, is lined with various corrosion-resistant or wear-resistant materials.

- Fully Enclosed Design: Prevents the medium from contacting the valve body internals, protecting against corrosion.

- Damage Prevention: The diaphragm’s design helps prevent damage to the valve body.

- Simple Operation: Can be operated manually or automatically.

- Adjustability: Flow can be regulated by adjusting the position (effectively the extension) of the diaphragm.