What is the Difference Between Cryogenic Ball Valves and High-Temperature Ball Valves?

As a common family of control valve, sanitary ball valves play a crucial role in the food and pharmaceutical industries. However, different working environments require different types of ball valves, among which cryogenic ball valves and high-temperature ball valves are two common variants. Let’s explore the differences between them.

Sanitary ball valves are known for their simple structure and ease of operation. However, when used in extreme high- or low-temperature conditions, their internal design, materials, and sealing principles undergo fundamental changes.

What Is a Cryogenic Ball Valve?

Cryogenic ball valves are specially designed to handle media at extremely low temperatures, below -46°C. They are not merely modified versions of standard ball valves but are comprehensively optimized in design, materials, and manufacturing processes to withstand “ultra-cold” environments.

The most recognizable feature of a cryogenic ball valve is its extended neck bonnet. This elongated stem is not for aesthetic purposes but serves a critical thermal isolation function. In cryogenic applications, the valve interior is cooled to extremely low temperatures by the medium, while the upper packing chamber and operating mechanism are exposed to ambient temperatures. The significant temperature difference can cause moisture in the air to condense and freeze around the stem, leading to packing failure and stem seizure. The extended neck increases the heat transfer distance, effectively maintaining the packing chamber above freezing, ensuring proper packing function, and preventing operators from frostbite due to contact with the ultra-cold stem.

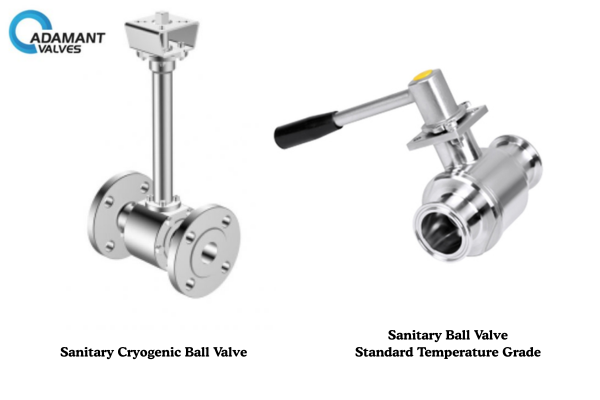

Fig 1. The difference in appearance design between cryogenic ball valves and standard ball valves.

What Materials Are Used in Cryogenic Ball Valves?

Unlike standard ball valves, which often use carbon steel or 304 stainless steel, cryogenic ball valves strictly employ austenitic stainless steels (such as 304L or 316L) or low-temperature nickel steels. The crystalline structure of these materials ensures excellent toughness and impact resistance even at temperatures as low as -100°C or below, minimizing the potential for brittle fracture.

The materials for the sealing system are also specially selected. While standard ball valves often use polytetrafluoroethylene (PTFE) for soft sealing, PTFE shrinks and becomes brittle at ultra-low temperatures, losing its sealing effectiveness. Cryogenic ball valves, hence, use specially formulated modified PTFE or other polymeric materials that retain elasticity in low-temperature environments.

What Is a High-Temperature Ball Valve?

Both high-temperature and cryogenic ball valves operate on the same basic principles, but they serve opposite extremes of temperature, leading to distinct differences in design and material selection.

High-temperature ball valves are specifically designed for service at temperatures above 200°C. Their core design objective is not only to withstand high temperatures but also to address challenges such as material strength degradation, creep, oxidation, and significant thermal expansion. Therefore, high-temperature ball valves must use materials that maintain strength and resist oxidation under elevated temperatures.

Typically, the valve body and ball of high-temperature ball valves are made of chromium-molybdenum steel or heat-resistant stainless steel (e.g., 310S), as alloying elements like chromium and molybdenum significantly enhance high-temperature strength and creep resistance. The stem is often made of high-temperature alloys such as Inconel to resist galling and seizing under high temperatures. Since sealing materials are in direct contact with high-temperature media, and standard PTFE would melt or decompose, more heat-resistant materials are chosen. Flexible graphite is the most commonly used high-temperature sealing material, capable of withstanding temperatures above 600°C in inert atmospheres while offering excellent self-lubrication and chemical stability.

High-temperature ball valves do not feature the extended neck bonnet of cryogenic valves. Instead, they have thicker valve walls to withstand pressure under high temperatures. The most critical structural consideration is the clearance design for internal moving parts, which must include precise expansion allowances to prevent thermal seizure.