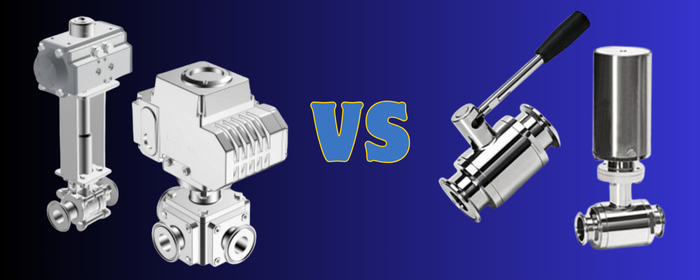

Titanium vs. Stainless Steel Sanitary Ball Valves

Choosing the right materials is a critical decision, since it directly impacts the quality of sanitary ball valves. Titanium and Stainless Steel stand out because of their superior performance. While both are excellent, they serve different purposes. Understanding their unique properties will guide you to the correct choice.

Stainless Steel Sanitary Ball Valves

Stainless steel is the most common material for sanitary ball valves. Its popularity comes from a strong balance of properties. It offers good corrosion resistance. It also provides high strength and is cost-effective. For many processes in the food, beverage, and pharmaceutical industries, stainless steel is perfectly adequate. It handles clean-in-place (CIP) chemicals and high-purity water very well. Its durability ensures a long service life in most standard environments.

Stainless steel sanitary ball valves recommendation

- AV-2MFC Sanitary Ball Valves with Tri-clamp Ends

- AV-2SV Stainless Steel V-Port Ball Valve

- AV-2MEC Encapsulated Sanitary 3 Piece Ball Valve with ISO 5211 Mounting Pad

However, stainless steel does have a weakness. It is that stainless steel can be vulnerable to chlorides. As a result, in applications where chloride ions are present, pitting and crevice corrosion may occur. This becomes a concern when it involves certain disinfectants or the processing of salt-containing products. Once corrosion starts, sterility is compromised and leads to product contamination. There is no doubt that a more robust material is needed for these more aggressive conditions. This is where titanium has a very strong advantage.

Titanium Sanitary Ball Valves

Compared to other metals, such as stainless steel, titanium provides a higher degree of resistance to corrosion, virtually immune to chloride attack. Such properties make it ideal for applications based on harsh chemicals, saltwater, or certain aggressive media. Its passive oxide layer is very stable and self-repairing. This outstanding level of corrosion protection means the highest level of product integrity in critical processes.

Titanium sanitary ball valves recommendation

- AV-2TR Sanitary Titanium Regulating Ball Valve

- AV-5BT Sanitary Titanium Sleeve Ball Valve T04

- AV-2TW Sanitary Titanium 3-Way Ball Valve

However, this advantage comes with some trade-offs. The superior corrosion resistance of titanium also means it comes at a significantly higher cost. The raw material cost is higher, and the machining process is also more difficult and costly. Furthermore, when it comes to strength, titanium is inferior to some high-grade stainless steels. Titanium is more prone to seizing or wear under certain mechanical conditions. You must carefully weigh these factors.

How to choose

So, how do you decide? The choice is often straightforward. If your process uses pure water, mild acids, and standard CIP procedures, a stainless steel valve is likely the best fit. It provides reliable performance at a reasonable cost. It is the workhorse of the industry for good reason.

You should seriously consider titanium when your process faces unique challenges. If you are handling strong oxidizing agents, salt brines, or other highly corrosive fluids, titanium is the safer choice. Its resistance to pitting guarantees a longer valve life and protects your product from metal ions. It is the specialist material for the most demanding environments.

In the End

The question is not about which material is objectively better. It is about which one is better for your specific application. Evaluate the chemicals in your process. Consider your requirements for product purity and your budget constraints. For most standard duties, stainless steel offers outstanding value and performance. For the toughest corrosive challenges, investing in titanium is a wise decision for long-term reliability and safety. Making the right choice ensures your operation runs smoothly and your products remain uncontaminated.