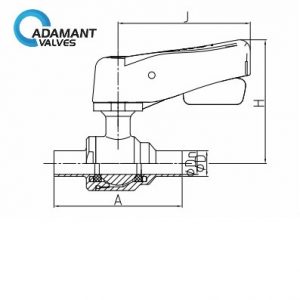

AV-2-S0552 Electric Actuated High Pressure Stainless Ball Valves 24 VAC – On/Off Version (1-1/2 NPT)

| Parameter | Details |

| Size | 1-1/2 NPT |

| Material | Stainless Steel |

| Seal Options | Braided Graphite/Viton |

Electric Actuated High Pressure Stainless Ball Valves 24 VAC – On/Off Version (1-1/2 NPT) Description

Electric Actuated High Pressure Stainless Ball Valves 24 VAC – On/Off Version (1-1/2 NPT) serve as control valves in sanitary fluid handling systems requiring high pressure tolerance. They find application in industrial processes where precise flow isolation and material integrity are critical.

Key Features:

– Electric Actuation: Employs a 24 VAC actuator that facilitates on/off control for streamlined process automation.

– High Pressure Rating: Engineered for operation at 2000PSI, making it suitable for systems with elevated pressure demands.

– Corrosion Resistant Construction: Fabricated from stainless steel to maintain integrity in aggressive environments.

– Sealing Efficiency: Utilizes braided graphite/Viton seals that withstand variations in temperature and chemical exposures.

– Operational Timing: Completes a full operating cycle in 30 s, enabling predictable process control.

Electric Actuated High Pressure Stainless Ball Valves 24 VAC – On/Off Version (1-1/2 NPT) Specifications

| Specification | Details |

| Size | 1-1/2 NPT |

| Material | Stainless Steel |

| Pressure | 2000PSI |

| Seal Options | Braided Graphite/Viton |

| 90° Cycle Time | 30 s |

| Voltage | DC 24 |

*The above product information is based on theoretical data and is for reference only. Actual specifications may vary.

Electric Actuated High Pressure Stainless Ball Valves 24 VAC – On/Off Version (1-1/2 NPT) Applications

- Food & Beverage: Implements sanitary fluid control for processing liquids in environments with stringent hygiene requirements.

- Pharmaceutical: Supports isolation of process streams to maintain product integrity and compliance.

- Water Treatment: Controls fluid flow in systems requiring precise and controlled valve actuation.

- Chemical Processing: Manages high pressure fluid delivery in applications involving aggressive chemical media.

- Bioprocessing: Facilitates regulated operation in systems needing dependable, electrically actuated control.

Reviews