Category: Valve Operation

Manual Valves vs. Pneumatic Valves vs. Electric Valves: How to Choose

Manual Valves, Pneumatic Valves, and Electric Valves Manual Valves are the most basic and traditional type. An operator turns a handwheel, lever, or gear. This mechanical action (via a stem, nut, etc.) moves the valve’s internal part (like a gate, ball, or disc) to open, close, or adjust the flow. Simple as that. Pneumatic Valves run on […]

Read more9 Common Misconceptions in Installing Sanitary Valves

In water supply and industrial piping systems, the quality of valve installation directly impacts the system’s reliability, maintenance efficiency, and service life. Although the installation process may seem straightforward, hidden risks are often introduced due to negligence of details. This article outlines nine common misconceptions encountered during the installation of sanitary valves, helping engineers and […]

Read moreWafer Valves: The Compact and Efficient Solution for Flow Control

In industrial piping systems, valve selection directly impacts cost, efficiency, and reliability. Among various valve designs, the wafer valve stands out as an excellent solution for applications where space and budget are constrained, thanks to its unique design concept. This article will explore the key features, installation process, common types of wafer valves, and clarify the distinction […]

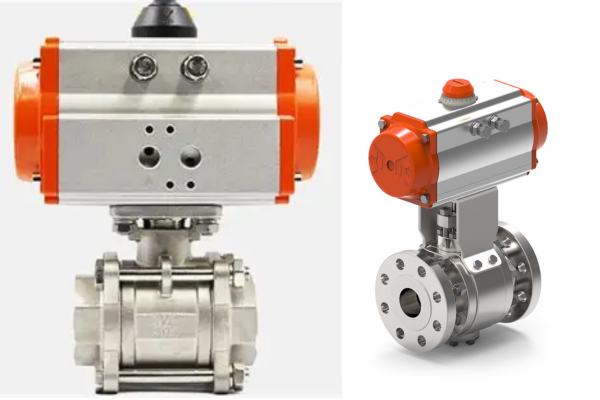

Read moreStructure of Pneumatic Ball Valves

A pneumatic ball valve is a device that uses compressed air to open or close a line of flow rapidly by means of a rotating ball. The performance of this machine depends on the precise and reliable work of each of its parts. Valve Body Assembly The pneumatic valve usually comprises essential parts such […]

Read moreSanitary Valve Seal Materials Guide

In hygienic process industries such as food & beverage, pharmaceuticals, and biotechnology, valves are not just devices for controlling fluid flow—they are critical barriers that ensure product quality and safety. A minor seal failure can lead to contamination of an entire batch, production line shutdown, or even serious sanitary incidents. One of the key factors […]

Read morePneumatic vs. Electric Actuators in Pharmaceutical Manufacturing

In the pharmaceutical industry, particularly within GMP (Good Manufacturing Practice) critical zones, pneumatic actuation is the absolute mainstream and preferred choice. Electric actuation, on the other hand, is applied in specific non-critical or modulating scenarios. Why Does the Pharmaceutical Industry Favor Pneumatic Actuation? The dominance is rooted in its ability to meet the pharmaceutical industry’s […]

Read moreHow Are Sanitary Valves Corroded? – 6 Forms of Corrosion and Maintenance Methods

Valve corrosion is one of the main causes of valve failure. It can lead to leaks, contamination, and even safety incidents. Sanitary valves have higher requirements for corrosion resistance. Why Do Valves Corrode? Corrosion is the process by which metals gradually return to their ore state through natural processes. A key electrochemical reaction is involved […]

Read moreHow to Properly Select and Use Electric Valve Actuators for Sanitary Applications

Electric valve actuators are a critical component in sanitary processing systems, providing the important interface between automated controls and fluid handling in pharmaceutical, food and beverage, and biotech applications. Unlike industrial environments, sanitary applications require outstanding cleanliness, corrosion resistance, and validation capabilities. This guide provides an overview of best practices for actuator selection and installation […]

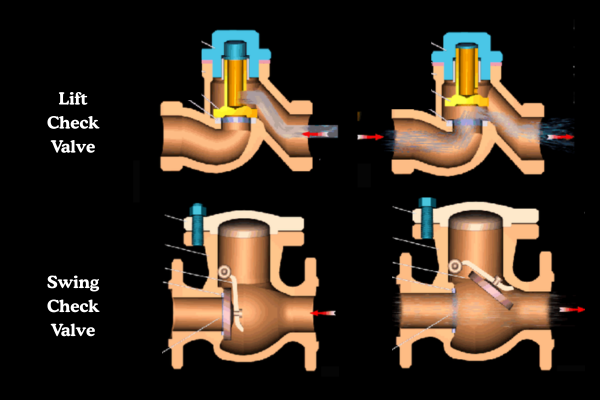

Read moreSingle Check Valve vs. Double Check Valve

What is a Single Check Valve? A single check valve, as the name suggests, usually consists of a single flap. The flap is fixed to the valve cover and operates by rotating to open or close the valve. When fluid flows forward, the flap rotates upward to open the valve, allowing fluid to pass through […]

Read moreBuying Guide: Understanding the Types of Sanitary Ball Valves

Clamp-type, weld-type, three-piece, full bore… There are various types and choices for sanitary ball valves. So, what are the characteristics of each type, and what other types of sanitary ball valves are available besides these? Classification by Connection Type The connection type is the primary dimension when selecting a sanitary ball valve. It directly relates […]

Read more