Globe Valves vs. Ball Valves

Globe valves excel in precise flow control & throttling, while ball valves are ideal for quick on/off service with minimal pressure drop.

Differences between Globe Valves and Ball Valves

1. Different Working Principles

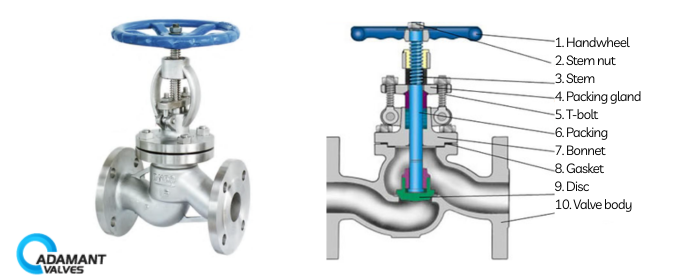

A Globe Valve has an internal disc that moves up and down, acting like a plug, and a seat. By rotating the handwheel, the stem drives the disc to move vertically away from or press against the seat, thereby achieving opening and closing. This process is similar to plugging a bottle with a stopper.

Globe Valve Structure

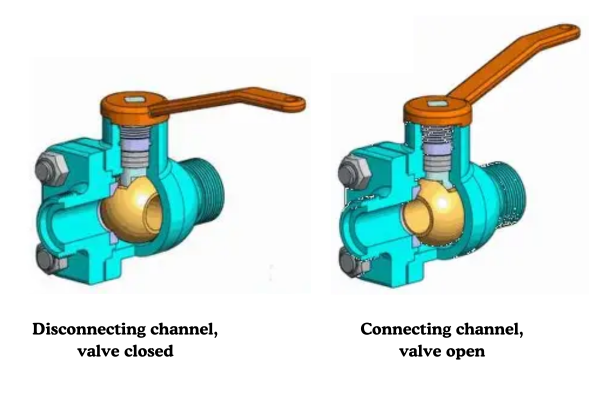

The core of a Ball Valve is a sphere with a through-hole. By rotating the handle 90 degrees, the through-hole in the ball is aligned with the pipeline direction (fully open) or perpendicular to it (fully closed). It operates much like switching a railroad track.

How the Ball Valves work

2. Different Functions

The primary function of a Globe Valve is regulation. By raising or lowering the disc, it can effectively throttle and regulate flow. Therefore, globe valves are preferred where precise control of flow or pressure is required, such as in laboratory equipment, heating or cooling systems.

The main purpose of a Ball Valve, however, is on/off service. It’s designed for quick, complete opening or shut-off of flow. In the fully open state, its flow passage is nearly the same diameter as the pipeline. Fluid resistance is very low, resulting in minimal pressure drop. Consequently, ball valves are the first choice for main pipelines where regulation is not needed, and only full open or full close operation is required.

3. Different Flow Resistance

When a Globe Valve closes, pressure must be applied to the disc to force the sealing surfaces to prevent leakage. Because the fluid must change direction within the valve body, the flow path is tortuous, resulting in high flow resistance and a significant pressure drop.

Ball Valves have low fluid resistance. Full-bore ball valves basically have no flow resistance, are easy to operate, and open/close rapidly. It only takes a 90-degree rotation, a quarter turn, from fully open to fully closed, facilitating remote control.

4. Differences in Sealing

In a Globe Valve, the disc and seat are continuously exposed to the scouring effect of high-velocity fluid during regulation, making them prone to wear and potential internal leakage. Thus, there is a potential leakage point. Ball valves are different. When fully closed or open, the sealing surfaces are isolated from the fluid, resulting in minimal wear. Especially for ball valves using soft seals (like PTFE), they can achieve zero leakage and offer very reliable sealing performance.

| Feature | Globe Valve | Ball Valve |

| Working Principle | Disc (plug) moves vertically along the seat centerline | Perforated ball rotates 90° to open/close |

| Primary Function | Precise flow regulation, reliable shut-off | Quick full open/close, flow passage or shut-off |

| Flow Resistance | High | Very Low |

| Opening/Closing Speed | Slow | Fast |

| Sealing & Leakage | Good sealing, but disc prone to wear, potential internal leak | Excellent sealing performance, minimal leakage |

| Use scenarios | Requiring throttling and regulation | Requiring quick on/off and full bore |

Sanitary Globe Valves and Sanitary Ball Valves

Sanitary valves are primarily used in industries with extremely high hygiene and cleanliness requirements, such as food, beverage, pharmaceuticals, and bioengineering. Their core differences are still based on the fundamental characteristics of globe and ball valves. However, in sanitary design, these characteristics are further enhanced.

In the sanitary field, a typical globe valve often appears as a Sanitary Diaphragm Valve. Its greatest advantage is that the fluid only contacts one side of the diaphragm and is completely isolated from the stem and other mechanical components. It is suitable for applications requiring flow regulation or handling fluids containing particles or high-viscosity materials, such as jam, dairy products, and pharmaceutical liquid distribution systems.

- Sanitary Diaphragm Valves with Tri-clamp Ends, Manual Type, Plastic Handwheel

- 316L Sanitary Diaphragm Valves

How A Sanitary Diaphragm Valve Works

Full-Port Ball Valves are the mainstream in Sanitary Ball Valves. The full-port design ensures fluid passes through unobstructed with no areas for material entrapment. Sanitary ball valves are widely used in applications requiring quick shut-off and extremely high demands for cleaning and sterilization, such as purified water systems, Water for Injection (WFI) systems, beer and beverage pipelines, and CIP return lines.

- Sanitary 4-Way Cross Ball Valve with Tri-Clamp Ends

- Sanitary Ball Valves with Tri-clamp Ends, Pneumatic Type