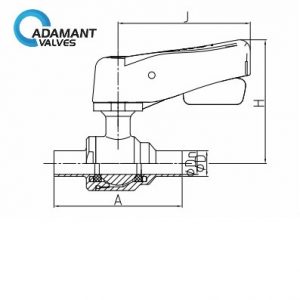

AV-2-S0541 Electric Actuated High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT)

| Parameter | Details |

| Size | 3/4 NPT |

| Material | Stainless Steel |

| Seal Options | Braided Graphite/Viton |

Electric Actuated High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) Description

Electric Actuated High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) are designed for precise fluid control in sanitary and high-pressure systems. These valves are commonly used in food processing, pharmaceuticals, water treatment, and chemical processing industries to maintain process integrity under elevated pressure conditions.

Key Features:

– Electric Actuation: Utilizes an AC 110 power supply that directly drives the valve operation, supporting accurate on/off control.

– High Pressure Rating: With a pressure capacity of 2000 PSI, the valve accommodates demanding fluid handling systems.

– Stainless Steel Construction: Ensures compatibility in sanitary environments and provides resistance against corrosion.

– Advanced Sealing: Incorporates braided graphite/Viton seals to secure tight closure and mitigate leakage risks.

– Defined Cycle Time: Operates with a 20-second cycle time, enabling predictable switching performance.

Electric Actuated High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) Specifications

| Parameter | Details |

| Size | 3/4 NPT |

| Material | Stainless Steel |

| Pressure | 2000 PSI |

| Seal Options | Braided Graphite/Viton |

| 90° Cycle Time | 20 s |

| Voltage | AC 110 |

The above product information is based on theoretical data and is for reference only. Actual specifications may vary.

Electric Actuated High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) Applications

Food Processing: Employed in systems requiring sanitary fluid management for food and beverage production.

Pharmaceutical: Utilized in processes that demand precise control and contamination prevention in active pharmaceutical ingredient production.

Water Treatment: Implements controlled flow in treatment plants where consistent pressure management is critical.

Chemical Processing: Supports fluid routing in chemical facilities that operate under elevated pressure conditions.

Biotechnology: Serves in lab-scale systems needing stringent control over sanitary fluid movement.

Reviews