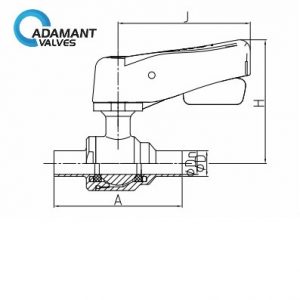

AV-2-S0637 Electric Actuated PVC Ball Valves 110 VAC with EPS Positioner 4-20mA Input (3/4 NPT)

| Parameter | Details |

| Size | 3/4 NPT |

| Material | PVC |

| Seal Options | Teflon/EPDM |

Electric Actuated PVC Ball Valves 110 VAC with EPS Positioner 4-20mA Input (3/4 NPT) Description

This product is an electric actuated valve used for controlling fluid flow in sanitary applications. It meets process requirements in industries such as food processing, pharmaceutical production, water treatment, and biotechnology by combining a PVC body with integrated EPS positioner technology.

Key Features:

– Electric Actuation: Utilizes a 110 VAC supply integrated with an EPS positioner and a 4-20 mA input to achieve controlled valve positioning.

– Material Construction: Constructed from PVC with Teflon/EPDM seals to ensure compatibility with various sanitary fluids.

– Cycle Performance: Achieves a 90° cycle in 21 seconds for consistent actuation timing.

– Pressure Handling: Rated for up to 232 PSI, meeting the demands of moderately pressurized sanitary systems.

– Integration Capability: The EPS positioner facilitates closed-loop control in automated process environments.

Electric Actuated PVC Ball Valves 110 VAC with EPS Positioner 4-20mA Input (3/4 NPT) Specifications

| Specification | Details |

| Size | 3/4 NPT |

| Material | PVC |

| Pressure | 232 PSI |

| Seal Options | Teflon/EPDM |

| 90° Cycle Time | 21 s |

| Voltage | AC 110 |

The above product information is based on theoretical data and is for reference only. Actual specifications may vary.

Electric Actuated PVC Ball Valves 110 VAC with EPS Positioner 4-20mA Input (3/4 NPT) Applications

- Food & Beverage: Used to control fluid flow in sanitary processing systems for dairy and beverage production.

- Pharmaceuticals: Applied in processes requiring strict sanitary conditions and controlled fluid isolation.

- Water Treatment: Employed in filtration and treatment systems to manage water flow and prevent contamination.

- Chemical Processing: Utilized in systems where precise separation of fluids and chemical isolation is critical.

- Biotechnology: Integrated into automated processes for accurate dosing and fluid management in bioprocessing.

Reviews