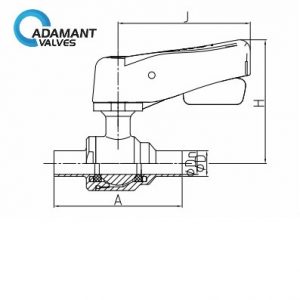

AV-2-S0573 Explosion Proof High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT)

| Parameter | Details |

| Size | 3/4 NPT |

| Material | Stainless Steel |

| Seal Options | Braided Graphite/Viton |

Explosion Proof High-Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) Description

Explosion Proof High Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) are designed for controlled fluid isolation in systems with high pressure and potential ignition risks. These valves are applicable in facilities where strict measures for hazardous atmospheres are required.

Key Features:

– Explosion Proof Construction: The valve housing and internal components are configured to limit spark propagation in hazardous environments.

– High Pressure Capability: Engineered to operate at 2000PSI, the design accommodates systems under significant pressure.

– Material Integrity: Constructed from stainless steel to minimize corrosion and withstand harsh operating conditions.

– Seal Design: Incorporates braided graphite/Viton seals to maintain integrity during repetitive 90° cycle operations lasting 20 s.

– Electrical Operation: Operates on AC 110, allowing integration into standard industrial power systems.

Explosion Proof High-Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) Specifications

| Specification | Details |

| Size | 3/4 NPT |

| Material | Stainless Steel |

| Pressure | 2000 PSI |

| Seal Options | Braided Graphite/Viton |

| 90° Cycle Time | 20 s |

| Voltage | AC 110 |

*The above product information is based on theoretical data and is for reference only. Actual specifications may vary.

Explosion Proof High-Pressure Stainless Ball Valves 110 VAC – On/Off Version (3/4 NPT) Applications

- Chemical Processing: Utilized to isolate and regulate high-pressure fluids in systems requiring explosion-proof components.

- Petrochemical: Applied for on/off control in installations handling volatile substances under significant pressure.

- Industrial Manufacturing: Employed to manage and control fluid flow in production lines with potential ignition hazards.

- Water and Wastewater Treatment: Used in environments where precise isolation of high-pressure streams is necessary.

- Pharmaceutical: Integrated into controlled processing systems where measured fluid delivery under high pressure is critical.

Reviews