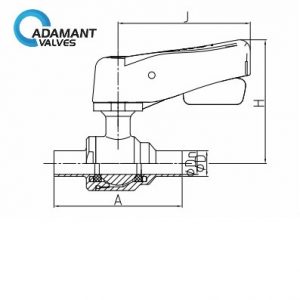

AV-2-S0577 Explosion Proof High Pressure Stainless Ball Valves 110 VAC – On/Off Version (2 NPT)

| Parameter | Value |

| Size | 2 NPT |

| Material | Stainless Steel |

| Seal Options | Braided Graphite/Viton |

Explosion Proof High-Pressure Stainless Ball Valves 110 VAC – On/Off Version (2 NPT) Description

This valve controls fluid flow in sanitary systems where explosion risks and high pressures require specific safety measures. It supports applications in chemical processing, oil and gas systems, industrial manufacturing, and pharmaceutical processing.

Key Features:

– Explosion Proof Design: Adheres to standards that mitigate ignition risks in hazardous environments.

– High Pressure Rating: Withstands pressures up to 2000PSI for demanding process conditions.

– Stainless Steel Construction: Offers resistance to corrosion and chemical exposure.

– Electric Actuation: Operates on AC 110 for precise on/off control.

– Seal Integrity: Employs braided graphite and Viton seals to maintain performance under high pressure.

Explosion Proof High-Pressure Stainless Ball Valves 110 VAC – On/Off Version (2 NPT) Specifications

| Parameter | Value |

| Size | 2 NPT |

| Material | Stainless Steel |

| Pressure | 2000PSI |

| Seal Options | Braided Graphite/Viton |

| 90° Cycle Time | 30 s |

| Voltage | AC 110 |

The above product information is based on theoretical data and is for reference only. Actual specifications may vary.

Explosion Proof High-Pressure Stainless Ball Valves 110 VAC – On/Off Version (2 NPT) Applications

- Chemical Processing: Controls high-pressure fluids while reducing ignition risks in corrosive environments.

- Oil & Gas: Manages fluid isolation in systems with strict explosion prevention requirements.

- Industrial Manufacturing: Provides on/off flow control for processes involving pressurized fluids.

- Pharmaceutical Processing: Maintains sanitary conditions during high-pressure material transfer.

- Food & Beverage: Supports fluid control in operations where sanitary standards and high pressure coexist.

Reviews