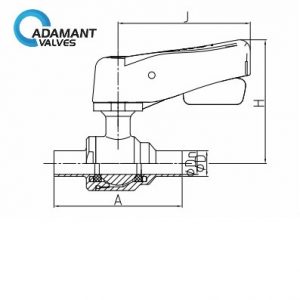

AV-2-S0567 Electric Actuated High Pressure Stainless Ball Valves 24 VAC with EPS Positioner 4-20mA Input (1-1/4 NPT)

| Parameter | Value |

| Size | 1-1/4 NPT |

| Material | Stainless Steel |

| Seal Options | Braided Graphite/Viton |

Electric Actuated High Pressure Stainless Ball Valves 24 VAC with EPS Positioner 4-20mA Input (1-1/4 NPT) Description

Electric Actuated High-Pressure Stainless Ball Valves 24 VAC with EPS Positioner 4-20mA Input (1-1/4 NPT) is configured for sanitary fluid control in industrial systems requiring accurate actuation and sealing integrity. It finds use in sectors such as food processing, pharmaceuticals, water treatment, and chemical processing by offering controlled fluid management under high pressure.

Key Features:

– Electric Actuation: Employs a 24 VAC signal with an integrated EPS positioner for direct feedback of valve status.

– High Pressure Endurance: Rated for 2000PSI, supporting operations in processes with elevated pressure conditions.

– Material Construction: Fabricated in stainless steel, ensuring compatibility with stringent sanitary standards.

– Seal Design: Utilizes braided graphite/Viton seals to manage leakage risks in demanding fluid control environments.

– Cycle Performance: Completes a 90° rotation in 30 seconds, which supports consistent operational timing.

Electric Actuated High-Pressure Stainless Ball Valves 24 VAC with EPS Positioner 4-20mA Input (1-1/4 NPT) Specifications

| Specification | Details |

| Size | 1-1/4 NPT |

| Material | Stainless Steel |

| Pressure | 2000PSI |

| Seal Options | Braided Graphite/Viton |

| 90° Cycle Time | 30 s |

| Voltage | DC 24 |

*The above product information is based on theoretical data and is for reference only. Actual specifications may vary.

Electric Actuated High-Pressure Stainless Ball Valves 24 VAC with EPS Positioner 4-20mA Input (1-1/4 NPT) Applications

- Food Processing: Facilitates controlled fluid transfer in sanitary environments.

- Pharmaceuticals: Manages isolated fluid streams during production cycles.

- Water Treatment: Regulates water flow and chemical dosing with secure sealing.

- Chemical Processing: Separates process streams under high pressure accurately.

- Industrial Manufacturing: Supports precise flow control within automated production systems.

Reviews